Galvanic Corrosion in Semi-Trailers: What It Is, How to Detect It and How to Prevent It

- -Steel chassis combined with aluminium or stainless steel fittings.

- -Stainless steel bolts in contact with painted steel sheet.

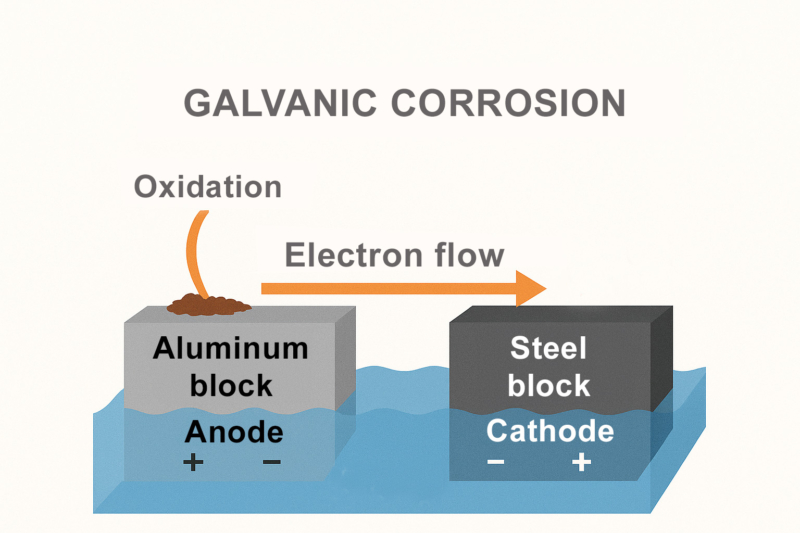

Factors that increase the risk of galvanic corrosion

Certain conditions make galvanic corrosion more likely to occur:

- -Moisture and rainwater, which act as an electrolyte.

- –Direct contact between different metals without insulation.

- –Significant differences in electrical potential between materials.

- -Failures in protective coatings, such as industrial paint, galvanizing, or anodizing.

Consequences of galvanic corrosion in semi-trailers

- –Thinning of structural components (chassis, side panels).

- -Failures in fittings and locking systems.

- -Appearance of rust and aesthetic deterioration.

- -Need for frequent maintenance and higher operating costs.

How to prevent galvanic corrosion in semi-trailers

Preventing galvanic corrosion requires a combined strategy that includes material selection, insulation, surface protection, and regular maintenance.

At Tisvol, we take it a step further by applying a rigorous protocol that safeguards all metal joints, maximizing the lifespan and reliability of our semi-trailers.

General prevention measures:

- -Selection of compatible materials to avoid direct contact between metals with large differences in electrochemical potential.

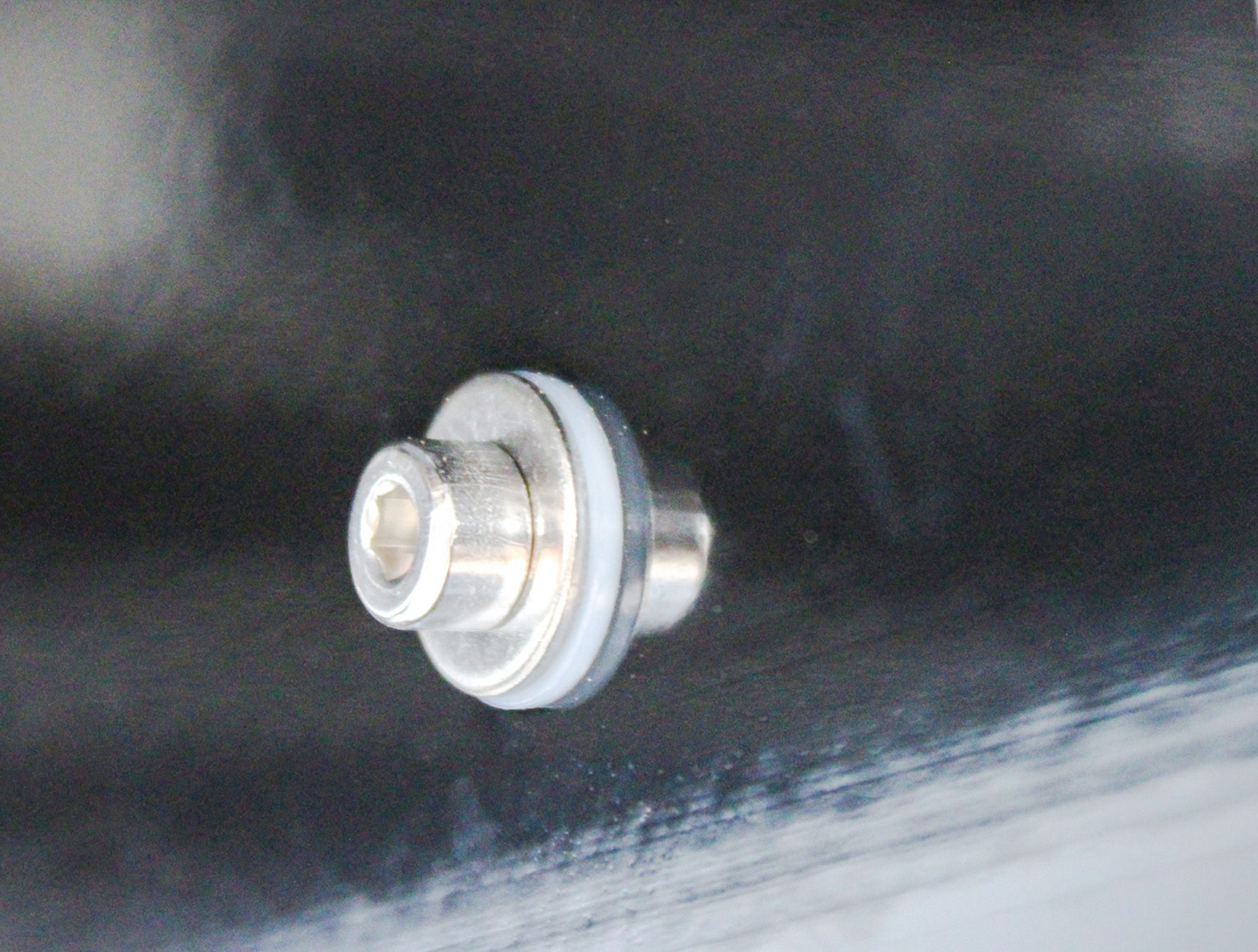

- -Electrical insulation using washers, spacers, or non-conductive coatings.

- -Surface protection with high-quality industrial paint, galvanizing, or special coatings.

- -Regular maintenance: cleaning off salt, water, or chemical residues and inspecting bolts and coatings.

Additional protection measures from Tisvol:

- -Protection at contact points between aluminium and steel components using insulators such as neoprene.

- -Entire bolt assembly treated with Dacromet or made of stainless steel.

- -Anti-corrosion treatments on key and sensitive components.

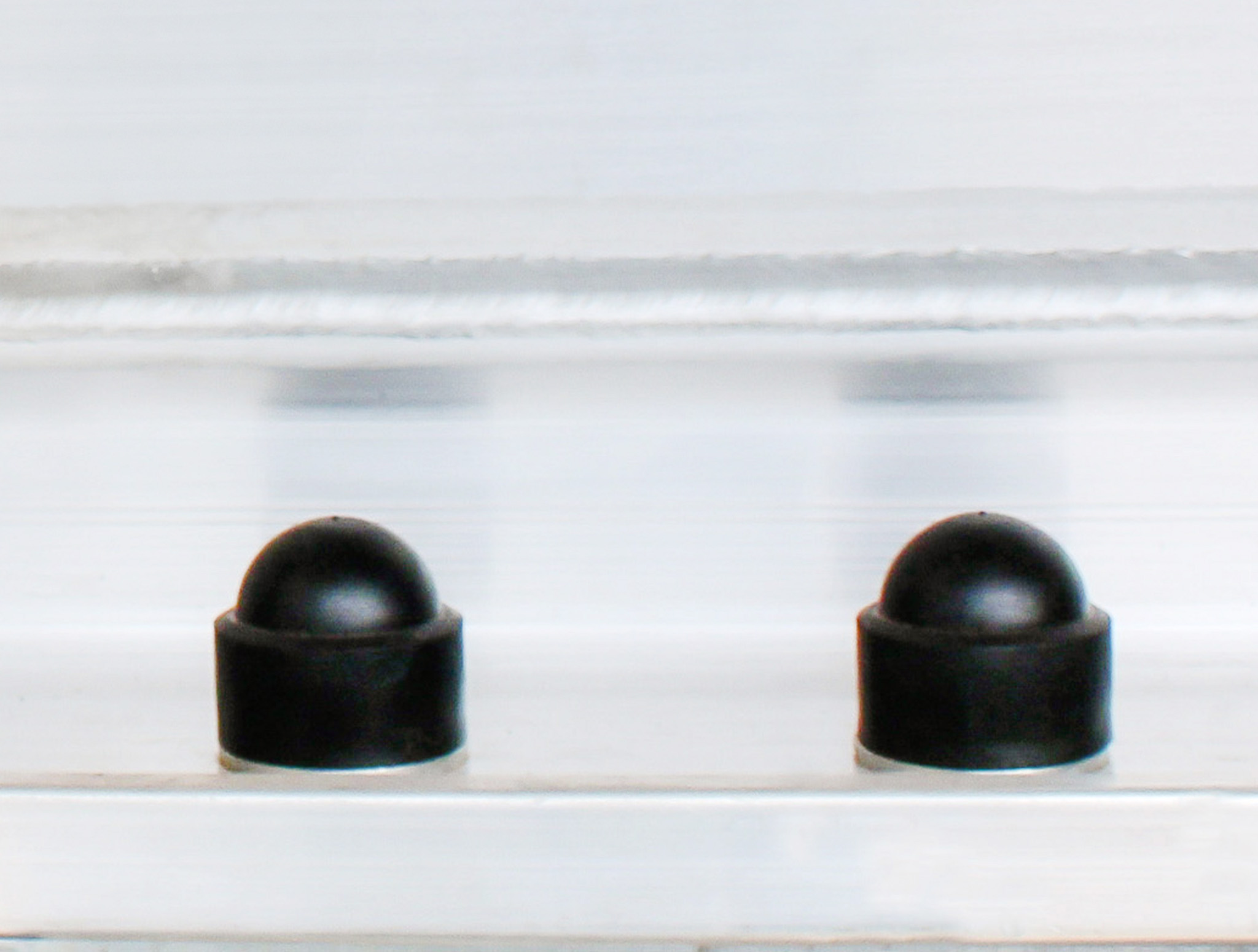

- -Installation of protective caps on chassis bolts.

Below is a table showing the protection measures applied between different materials:

| Materials | Applied solution |

|---|---|

| Aluminum + aluminum | Without a separating element |

| Aluminum + galvanized steel | Protective paint to prevent contact and oxidation |

| Aluminum + Magnelis steel | Installed rubber gasket |

| Fasteners on painted vehicles | Plastic washers between the bolts and the chassis beam to prevent oxidation between paint and steel |

| Fasteners on unpainted vehicles | Stainless steel washer between the bolts and the chassis beam to prevent oxidation |

| Joints between axles and chassis | Neoprene between metal surfaces |

Among the components protected against galvanic corrosion are:

Benefits of protecting your semi-trailers against galvanic corrosion

- -Longer lifespan and increased structural durability.

- -Reduced maintenance and repair costs.

- -Greater safety and reliability in cargo transport

- -Preservation of the semi-trailer’s appearance and resale value.

Preventing galvanic corrosion not only ensures the

durability of components but also guarantees the

quality and reliability of the vehicles.